Tackling the problem of plastic waste

Plastic waste is a big problem set to get even bigger over the next few decades. The amount of plastic waste we generate is projected to triple, rising from 353 million tonnes in 2019 to 1,014 million tonnes in 2060 (according to forecasts from the OECD’s Global Plastics Outlook). Two-thirds of plastic waste comes from packaging, a lot of it from single-use packaging, consumer products and textiles. Construction and transport also generate significant levels of plastic waste.

What’s the problem with plastic waste?

Currently, we deal with plastic waste in a variety of unsustainable ways. In the UK we bury around 50% of our plastic waste in landfills and increasingly burn it (18%). We only recycle 9-10% of our plastic waste streams and although these rates are projected to double by 2060, that will not match the expected trebling rate of plastic waste generation.

The UK is still exporting large amounts of plastic waste, over 600,000 tonnes in 2023 mainly due to a lack of recycling facilities. Most of the plastic waste was sent to Turkey (>150,000 tonnes) and Germany (60,000 tonnes). The UK also sent over 150,000 tonnes of plastic waste to non-OECD or developing countries including EU Member States, Bulgaria and Romania, as well as Egypt, and Malaysia and Vietnam in Asia.

In many countries with poor waste processing systems (often non-OECD countries), plastic waste ends up in the environment. If it is discarded or swept into rivers it then moves on to lakes and eventually the ocean. The UN estimates that 75 to 199 million tonnes of plastic is currently found in our oceans. Plastic never disappears, it just breaks down in the environment into smaller and smaller pieces until they are no longer visible to the naked eye and we call them microplastic particles. These microplastics end up in food chains, not just in marine organisms but also in tissues in the human body, and the health consequences of these pollutants are not yet understood (but we are running the experiment on a global scale).

Solutions for Plastic Waste Reduction

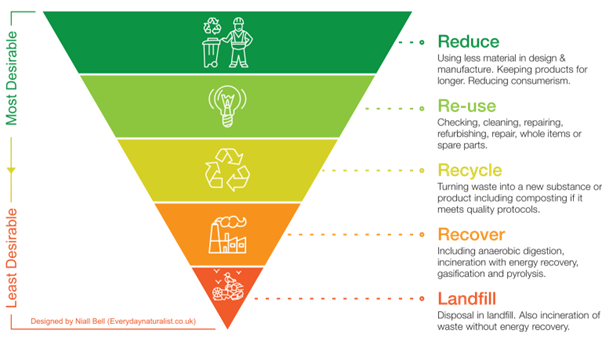

According to the five steps for tackling waste in the waste hierarchy, the most effective route to cutting waste would be to reduce production. But cutting production is a political hot topic. The UN is working towards a Global Plastics Treaty, a global consensus on ways to tackle the plastic waste problem. The last discussions on the Treaty were held in Canada in April 2024. Twenty-nine countries including Australia, Denmark, Portugal, the Netherlands and Nigeria, all signed a declaration, “the Bridge to Busan”, calling on all delegates to ensure that a reduction in plastic production was included in the Treaty. However, the UK and US did not support the proposal to cut plastic production, reportedly caving to pressure from lobbyists from the fossil fuel and petrochemical industries.

The Ellen MacArthur Foundation promotes a circular economy for plastic. They propose that the systems for using plastics need to be redesigned so that we focus on reuse, recycling or composting. They argue that reuse business models reduce the need for single-use plastic packaging and would be suitable for at least 20% of plastic packaging.

Loop is a packaging reuse initiative from waste management company TerraCycle. Loop works with food and beverage manufacturers and retailers in the USA, France and Japan to offer consumers products in durable packaging, much of it glass. Loop collects dirty, used packaging that consumers return to retailers, they clean them, so that food and beverage manufacturers can refill them and return them to the store as new products. The Loop system allows packaging to be reused until the end of its life, creating a circular system rather than resorting to the more common, single-use packaging. However, the reuse of packaging is still very much the exception. Most of the focus up till now has been on plastic recycling.

Plastic Recycling in the UK

The UK is developing its plastic recycling infrastructure. UK company, Viridor, opened their Avonmouth Polymers Reprocessing Facility (PRF) in 2022 where they produce recycled, food-grade PET that has been assessed as safe by the European Food Safety Authority. They aim to produce 18,000 tonnes of recycled, food-grade PET annually. The total output from this plant will be 60,000 tonnes of recycled plastic per year, harvested from bottles, pots, tubs and trays (PET, HDPE and PP), and marketed as alternatives to virgin plastic. However, the output of recycled plastic is considerably less than the quantity of residual waste they incinerate. Each year, the Avonmouth plant burns 320,000 tonnes of non-recyclable waste to generate heat and power (and CO2), more than five times the amount of plastic that they can recycle.

The current process for plastic recycling in the UK focuses on two main types of plastics: PET, from drinks bottles and takeaway food containers and HDPE, used in milk bottles. Bales of waste plastics are produced in materials recovery facilities by waste management companies like Recorra that are then sent for processing into single polymer flakes and pellets. The plastics are cut up by choppers to make flakes that are washed to remove dirt and glue. The washed flakes then pass through a separation tank where PET flakes sink to the bottom and HDPE flakes float. The cleaned flakes can be melted into pellets or sold as flakes. PET can be recycled around 10 times.

Start-ups innovating in plastic recycling

Although the waste management industry has been slow to innovate, some start-up companies are developing technologies to improve the efficiency of plastic recycling.

Circulyzer, a spin-out company from Montanuniversitaet Leoben in Austria offer services in the design and installation of new plants for processing post-consumer plastics using their centrifugal force separator technology. This wet-mechanical technology combines the plastic flake washing and separating steps and uses a flow-induced water vortex to improve the efficiency of separation. They claim to reach >95% material purity and recovery at a throughput of 9 tonnes/hour (78,000 tonnes/year; 24/7 operation) with a simple plant design that makes the process economical.

Dutch company, Umincorp, have a very different technical approach. Their patented Magnetic Density Separation technology uses strong magnets and a unique ferrofluid to separate plastics based on the density of individual particles. A single-step process sorts mixed plastic flakes into HDPE, PET and PP. The company sells HDPE, PET and high-grade PP recyclate to packaging and plastic manufacturers. They are also developing a deep flake sorting technology for small plastic particles to increase recovery rates. They aim to produce recycled plastics for specific polymer applications e.g., extrusion-grade HDPE and blow-mould-grade HDPE as well as specific colour plastics. They claim their sorting process doubles the recovery rate of plastic waste, at a lower cost and with higher accuracy than other technologies.

Exploring Big Corporations’Waste Management Strategies

The big drinks brands are transitioning to use more sustainable packaging, but are they moving quickly enough? Just to give one example – The Coca-Cola Company has a goal to make 100% of their packaging recyclable globally by 2025 and to use at least 50% recycled material in their packaging by 2030. They also have a waste & packaging collection strategy to collect and recycle a bottle or can for each one they sell by 2030. Here are a couple of examples of the work Coca-Cola are doing:

- transitioning all 500ml sparkling beverage bottles sold in Canada into 100% recycled plastic, excluding caps and labels, by early 2024 to save virgin plastic, reduce carbon emissions, and meet its sustainability targets;

- opened a new in-house production facility in Romania to supply rPET (recycled PET) for its 100% recycled bottle portfolio – apparently positioning the company to deliver almost 50% rPET use across its EU and Swiss markets by the end of the year (2023).

Advancing the Fight Against Plastic Waste

It will be a government policy that will drive the industry to reduce waste. The Global Plastics AI Policy Tool, developed by academics at UC Santa Barbara and UC Berkeley illustrates the importance of specific policy decisions. A cap that holds the production of virgin plastic at 2025 levels would have a big effect on waste as would setting a minimum recycled content for plastic materials. The latter policy would ensure plastics get recycled and then incorporated into new materials. Improved waste collection and processing systems would also have a big effect.

Viridor recommends that the plastics used in food and packaging should be restricted to just four types: drinks bottles (PET), milk bottles (HDPE), bottle caps/tops (PP) and films (LDPE). This would require banning certain materials e.g., the use of polystyrene for yoghurt pots. But simplification would make plastic recycling and reprocessing easier for everyone.

How can Strategic Allies help with your innovation challenges?

As an Open Innovation services company, Strategic Allies has extensive experience in the global search for innovative technologies, solutions, products, strategic alliances and other new business-generating opportunities across all sectors. If you’d like to find out more about how we can help you to explore and exploit new technologies and/or offer opportunities to differentiate your offerings, please contact John Allies at john@strategicallies.co.uk

References

- Plastic waste: Here’s what it could look like by 2060. https://www.weforum.org/agenda/2022/07/recycling-efforts-not-enough-to-solve-plastic-waste-problem/

- Growth in UK export for plastic packaging recycling in 2023 shows need for rethink on use of non-OECD https://www.recycling-magazine.com/2024/01/23/growth-in-uk-export-for-plastic-packaging-recycling-in-2023-shows-need-for-rethink-on-use-of-non-oecd/

- Viridor food-grade PET gets the green light from European Food Safety Authority. https://www.viridor.co.uk/news-and-insights/viridor-food-grade-pet-gets-the-green-light-from-european-food-safety-authority/

- Plastics recycling. https://www.which.co.uk/reviews/shopping-sustainably/article/how-to-recycle-in-the-uk-ajwEz4p63Qs6#plastics-recycling

- Developed countries accused of bowing to lobbyists at plastic pollution talks. https://www.theguardian.com/environment/2024/apr/30/developed-countries-accused-bowing-lobbyists-plastic-pollution-talks

- UN Environment Programme. https://www.unep.org/interactives/beat-plastic-pollution/

- The Loop system from TerraCycle. https://www.weforum.org/agenda/2023/10/reuse-packaging-loop-zero-waste-terracycle-tom-szaky/

- Recorra visits Viridor’s Plastic Recycling Facility https://www.recorra.co.uk/blog/view/paper-round-visits-viridors-plastic-recycling-facility

- Circulyzer https://circulyzer.at/en/start-english

- Umincorp https://umincorp.com/

- Viridor launches plan to achieve zero export of plastic waste https://www.viridor.co.uk/news-and-insights/viridor-launches-plan-to-achieve-zero-export-of-plastic-waste/

- Can AI Help Cut Plastic Waste From the Food System? https://civileats.com/2024/06/03/can-ai-help-cut-plastic-waste-from-the-food-system/

- The Coca Cola Company Sustainable Packaging https://www.coca-colacompany.com/sustainability/packaging-sustainability

- Article from Packaging Europe on The Coca Cola Company using recycled PET in Canada https://packagingeurope.com/news/500ml-sparkling-drink-bottles-from-the-coca-cola-company-shift-to-100-recycled-plastic-in-canada/10539.article

- Article from Packaging Europe on The Coca Cola Company using recycled PET in Romania Coca-Cola HBC’s Romanian in-house production facility drives 50% rPET goal for 2023 | Packaging Europe

- WasteOnline https://wasteonline.uk/blog-old/the-hierarchy-of-waste/